Frameless Glass Aluminum Handrail Track Floor Trough Guardrail Card

Slot

Basic Information

During the use of industrial aluminum profile frames, will you

encounter shaking, collapse, breakage, etc.?

1. Start with profile selection. The load-bearing of the aluminum

profile frame is mainly on the profiles used. If you want an

industrial aluminum profile frame structure, then you must choose a

specification with good quality and load-bearing standards when

selecting the model, otherwise there is no way to guarantee the

stability of the frame. Good-quality aluminum profiles are extruded

from high-quality aluminum rods, without any waste aluminum, and

the thickness of the oxide film reaches the standard. The aluminum

profile that meets the load-bearing standard is only selected

according to the load-bearing capacity of the frame, and the

profile with a small size or light profile cannot be selected

because the picture is cheap.

2. Start with the frame connection method. If the aluminum profile

frame is to be strong, it must use a strong connection method.

There are many connection methods for aluminum profile frames,

commonly used are corner fittings, built-in fittings, corner slot

fittings, connecting plates, hexagon socket bolts, anchor

connection pins, etc., but the strength of corner fittings and

hexagon socket bolts is the highest. Yes, if you want the frame to

be strong, you must use one of these two accessories, or you can

use them at the same time to fix them more firmly.

3. Start with the frame structure. The solid load-bearing of the

aluminum profile frame is not only related to the profile

specifications and accessories, but also has a lot to do with the

structure of the frame. If you want the frame structure to be

strong, you can appropriately increase the number of beams and

footings to ensure the stability of the frame.

Name

|

Handrail16

|

Material

| Zinc steel, aluminum alloy |

Surface

Treatment

|

Mechanical grinding, chemical treatment, surface heat treatment,

sprayed surface

|

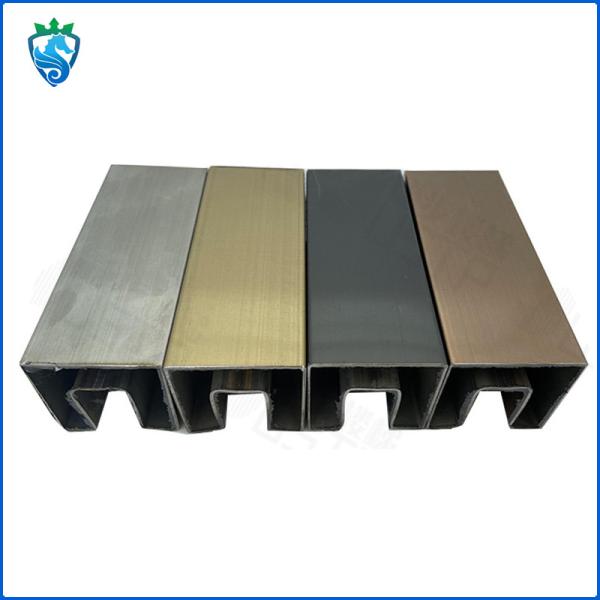

Colour

|

blue/ green or customized

|

Temper

|

T5-T8

|

Shape

| As customer's requestments |

Certification

|

ISO 90001,14001,45001;CQC;RoHS;

|

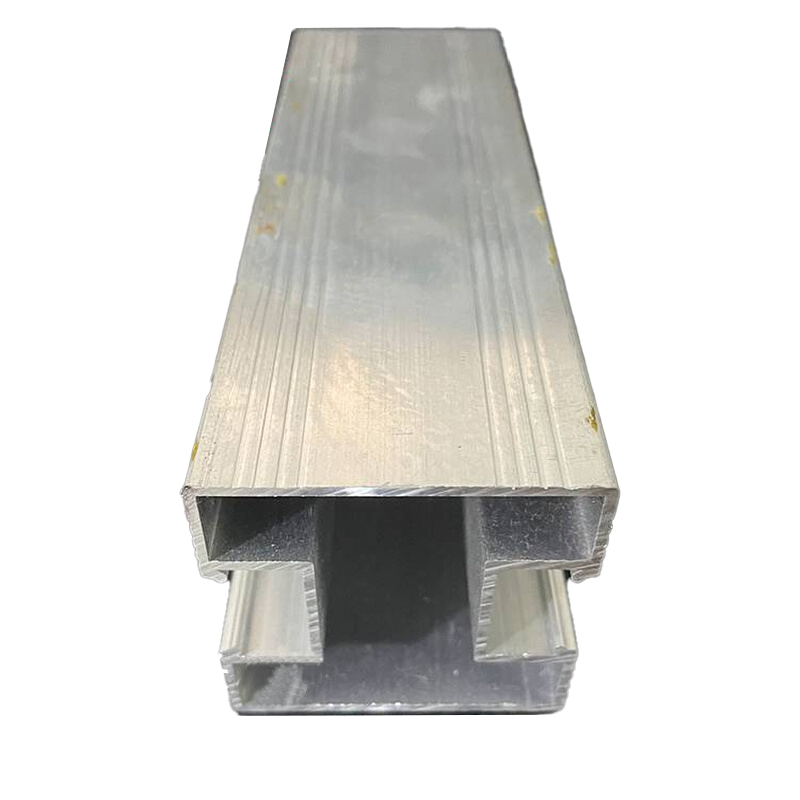

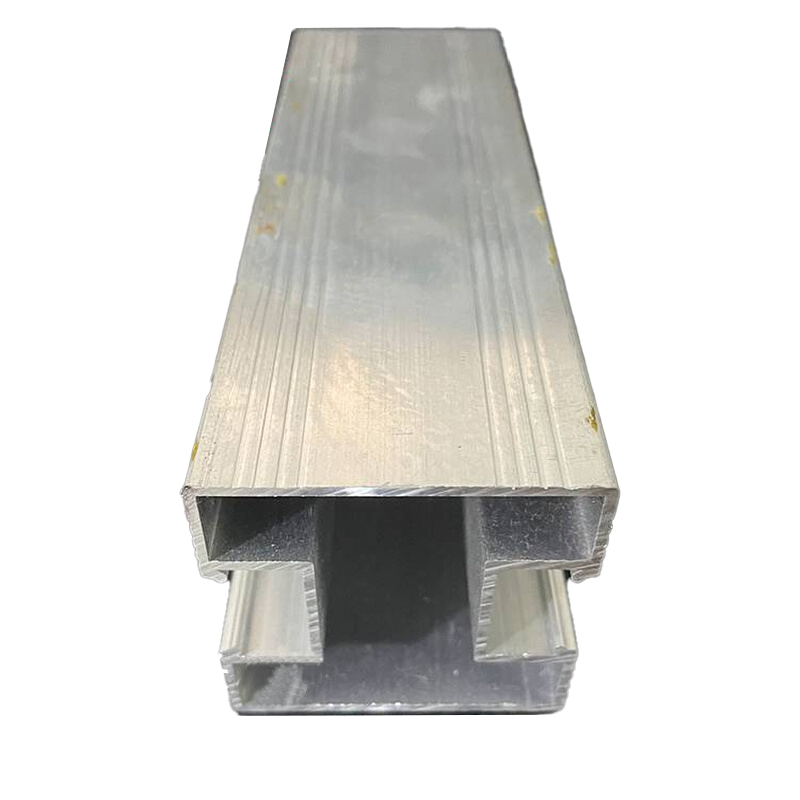

Product Display

Certificates and Honors

Company Profile

Jiangyin Longkang Metal Products Co., Ltd. is located in Zhouzhuang

Town, Jiangyin City - the largest aluminum extrusion profile

production base. Covering an area of more than 35,000 square meters

with more than 350 employees. We focus on metal customization,

special-shaped aluminum profiles, aluminum profiles, aluminum

tubes, rail transit series, doors and windows aluminum profiles,

heat sinks, CNC processed aluminum profiles, interior decoration

series, bending series, etc. We also have precision anodizing and

various surface treatments, such as PVC film, wood grain,

electrophoresis, powder coating, anodizing, etc. After more than 20

years of development, The company has become a modern aluminum

production enterprise with perfect quality management system.

Efficiently treating our customers as partners with sincerity,

specialization and satisfaction is our managerial principle.

Attributed to the backup of a dedicated technical team, filled with

wide and profound knowledge and practice in aluminum profile and

world trade for 20 years, the company owns rich experience in

product quality control and profile physical properties such as

Hardness, Stretchability, Flatness, Straightness, and Tolerance

etc. In line with the principle of sharing the preferential cost

and joint development, the company has formed an interest community

for years with its customers at home and abroad. Sincerely to build

up a pleasant mutual trust, cooperative, win-win and value-added

sustainable partnership is what we are achieving to grow together

with you!

The company has the ability to develop and design molds

independently, we can produce any extruded aluminum profiles

according to your mechanical drawing or sample. Longkang has 10

extrusion production lines (600-3500 tons), one automatic oxidation

electrophoresis production line, vertical and horizontal spraying

production line per each, and a variety of advanced supporting

production, processing and testing equipments. There are also CNT

digital control drilling and milling machine(CNC), double head saw,

hydraulic saw and punching machine in our processing workshop. The

complete technological process can benefit to reduce the production

turnover times for semi-finished products, to avoid the damage

during transportation, improve the production efficiency, reduce

the cost of production,and to ensure the quality and delivery time.

Factory display

FAQ

Q: How to place an order?

A: First let us know your requirement or application.

Secondly, we quote according to your request or our suggestion.

Third, the customer confirms the sample and makes a deposit for the

formal order.

Finally we arrange production.

Q: Are all color products the same finish?

A: No. With powder coatings, bright colors will be higher than

white or gray. Regarding the price of anodizing, the color will be

higher than the silver, and the black will be higher than the

color.